I need to do some final stuff to get ready to paint the guitar. I needed to make some fixture to hold the guitar while I paint it and still allow me to paint all the sides. And I need to find a way to hold it without me actually holding it.

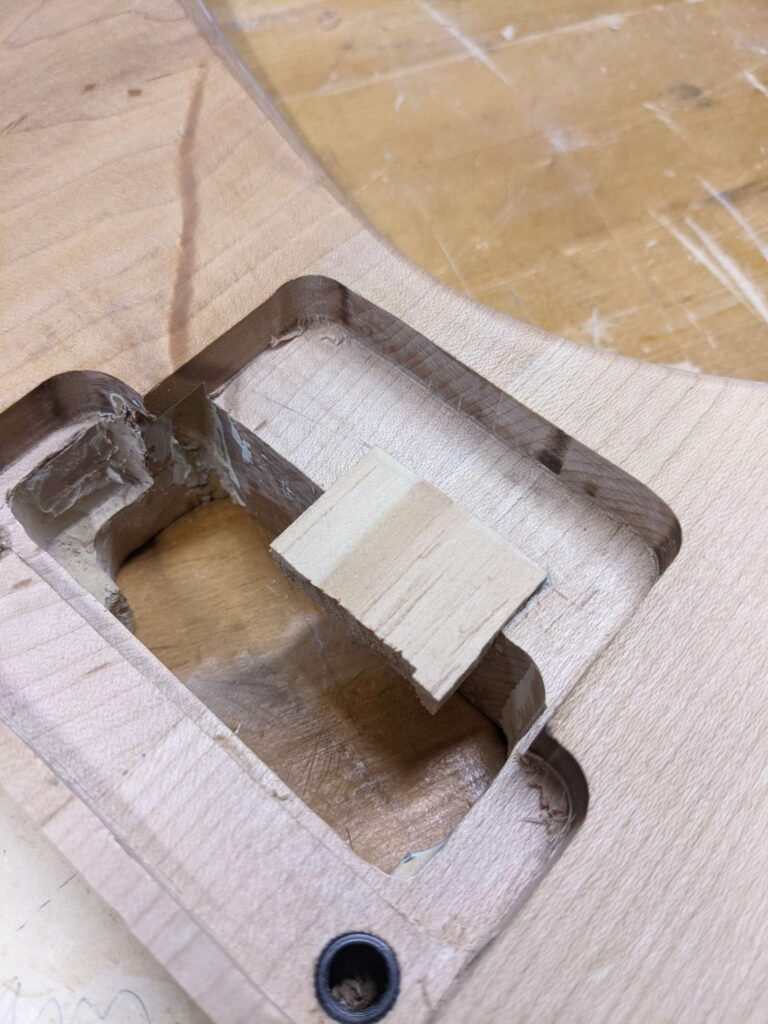

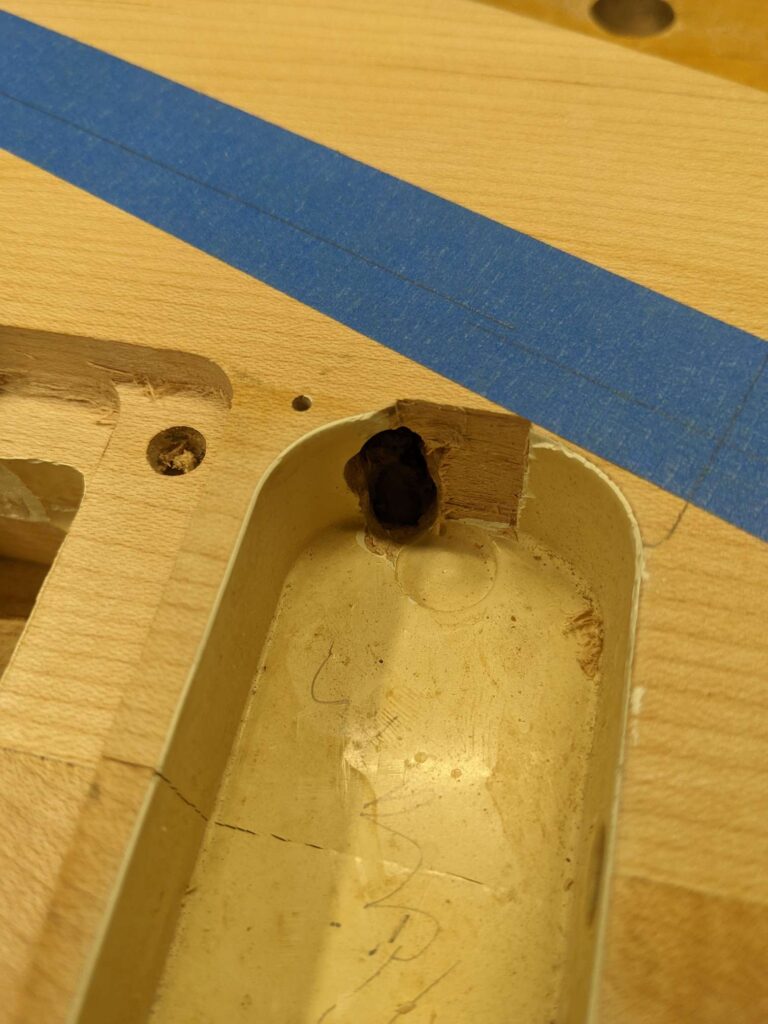

I used some scrap pine to make a fake neck that I can attach to the body. Then I used a piece of 3/4″ galvanized conduit (the stuff used to run wires in places the wire can’t be exposed). I flattened one end of the conduit in my vise and drilled some holes to mount it to my faux neck. The conduit was bolted to the pine neck thingy and voila!

To mount this to my workbench, I drilled a 3/4″ hole through a couple thicknesses of 2×6 that are glued and screwed together. This makes a solid 3″ long bearing surface to hold the overhang weight of the guitar body. This thing has to be strong enough to hold the guitar without me worrying (I’ll still worry). Luckily the conduit is slightly less than 3/4″ so it’s easy to turn and it does not have too much slop. I’ll use the tag team of my workbench vise and some screws to hold the fixture nice and solid.

I’ll do some final cleanup around the workshop and put drop cloths everywhere around the guitar.

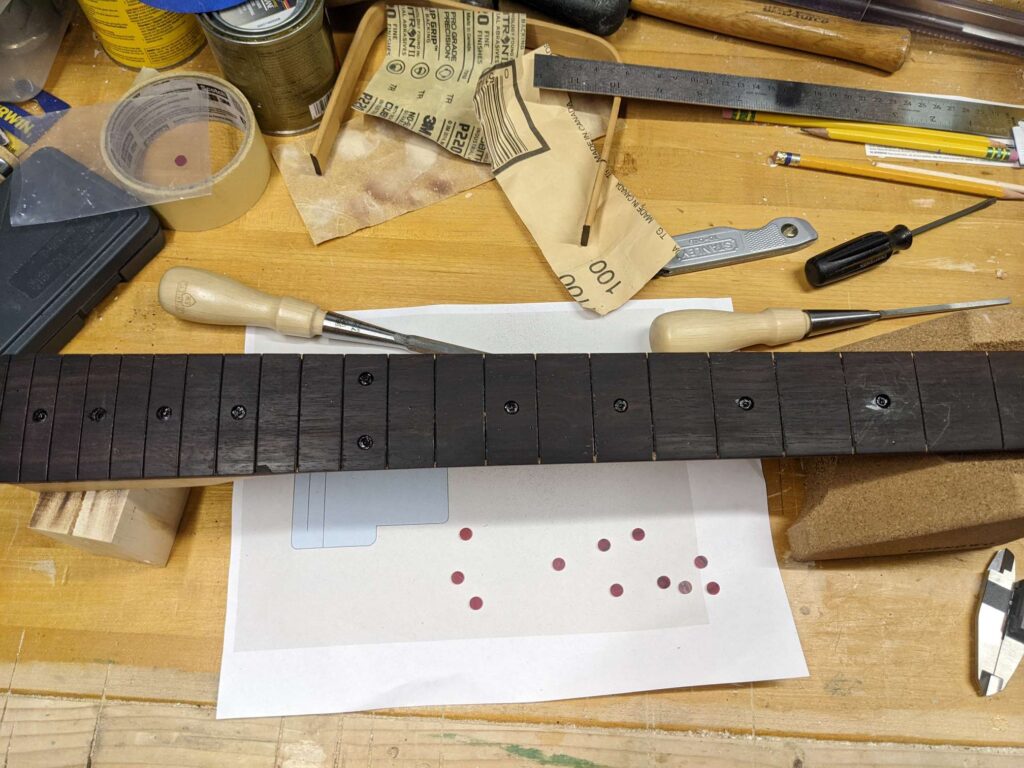

For the neck, I’ll just hang it from the ceiling and paint the headstock.

You must be logged in to post a comment.